Why Have a Mechanical Survey

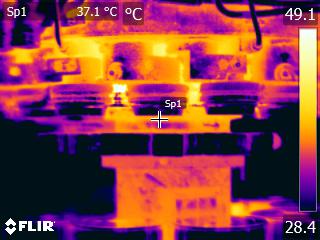

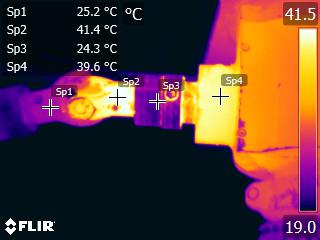

A.B. Thermographic Surveys are able to perform mechanical surveys across your whole plant. Looking for bearing defects, belt overheating, shaft alignment, gearbox overloading, oil levels and content of liquid in vessels. Surveys can also be carried out on individual machines looking at tooling and gearbox performance over time (either regular intervals during a production period, or on a weekly or monthly basis to look at degradation). Looking at the change in temperature of tooling during a running period could be used to help understand reasons for variations in repeatability of tooling. For example it may be one bearing overheating due to lack of lubrication that causes your product to creep out of its tolerance.

Thermal surveys can detect faults that are invisible to the naked eye. In many instances discovering a fault and planning maintenance is far more cost effective than waiting for a breakdown. The use of a high end thermal camera and the knowledge of a Cat 2 thermographic engineer give A.B. Thermographic Surveys the ability to assess your mechanical components and report on them, comparing them to alike items and manufacturers data sheets. In all instances when a fault is detected our engineer, with over 20 years mechanical experience, will give advice on remedial actions to be taken.

If you would like to speak to, or contact an Engineer please use the contact form or contact us on (01945) 739965.